Double Flanged Butterfly Valves are robust and versatile flow control devices designed for reliable performance in demanding industrial and commercial applications. With a secure double-flanged design, these valves provide excellent sealing, making them ideal for handling high-pressure and high-temperature fluids.

Manufactured using premium-grade materials, our Double Flanged Butterfly Valves ensure superior durability and corrosion resistance, even in challenging environments. These valves are widely used in industries such as water distribution, wastewater management, power plants, chemical processing, and oil and gas systems.

The double-flanged design offers a secure and stable installation, ensuring minimal vibration and enhanced safety. Available in various sizes, pressure ratings, and material configurations, these valves can be tailored to meet specific operational requirements, ensuring seamless integration into your system.

Each valve is rigorously tested to comply with international quality standards, guaranteeing dependable operation, reduced maintenance, and long service life. By selecting our Double Flanged Butterfly Valves, you invest in advanced technology that ensures efficient flow control, operational reliability, and cost-effectiveness for your applications. We also Provide API 609 Double Flanged Butterfly Valves,Water Treatment Double Flanged Butterfly Valves,Oil and Gas Flanged Butterfly Valves,HVAC System Butterfly Valves with Flanges,Cast Iron Double Flanged Butterfly Valves,Stainless Steel Double Flanged Butterfly Valves,Lugged and Flanged Butterfly Valves,Resilient Seated Double Flanged Butterfly Valves,High-Pressure Double Flanged Butterfly Valves

| Component | Material Specification |

| Body | CI / SGI / WCB / CF8 / CF8M |

| Disc | CI / SGI / WCB / CF8 / CF8M |

| Shaft | AISI- 410 / 304 / 316 |

| Seat | Nitrile / EPDM / Neoprene / Silicon / Viton. |

| Bush Bearing | Self Lubricating Sintered Bronze |

| Design Standard | As per IS- 13095 / BS- 5155 / BS EN - 593, AWWA - C - 504 |

| Pressure Rating | PN - 10.PN - 16 |

| Class | 125 / 150 |

| Temp. Range | -20° To + 180oC |

| Face to Face | ISO- 5752 / BS 5155 Wafer short / API 609 |

| Dimension | Hand lever - DN - 40 to ON 150 |

| Actuation By | Gear Operated DN - 200 to DN - 1200 |

| End Connections | Wafer- Flangeless & Double Flanged |

| Suitable for Mountinq Flanges | IS / ANSI / BS / DIN Standards |

| Testing Std. | BS 6755 (1) / API 598 / AWWA - C - 504 |

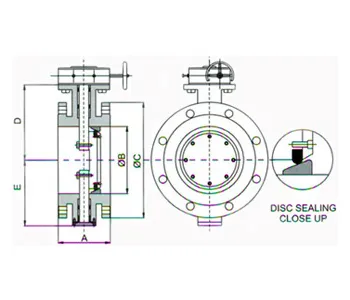

| Size | A | B | øC | D min | E min |

| DN 65 | 112 | 65 | 185 | 130 | 105 |

| DN 80 | 127 | 80 | 191 | 135 | 115 |

| DN 100 | 127 | 100 | 229 | 153 | 130 |

| DN 150 | 127 | 150 | 279 | 203 | 165 |

| DN 200 | 152 | 200 | 343 | 235 | 205 |

| DN 250 | 203 | 250 | 406 | 275 | 235 |

| DN 300 | 203 | 300 | 493 | 290 | 280 |

| DN 350 | 203 | 350 | 353 | 325 | 310 |

| DN 400 | 203 | 400 | 597 | 365 | 320 |

| DN 450 | 203 | 450 | 635 | 410 | 345 |

| DN 500 | 203 | 500 | 705 | 460 | 380 |

| DN 600 | 203 | 600 | 826 | 480 | 445 |

| DN 700 | 292 | 675 | 940 | 527 | 491 |

| DN 800 | 318 | 774 | 1046 | 587 | 545 |

| DN 900 | 330 | 877 | 1175 | 648 | 612 |

| DN 1000 | 410 | 977 | 1283 | 702 | 671 |

| DN 1100 | 440 | 1076 | 1389 | 756 | 725 |

| DN 1200 | 470 | 1175 | 1492 | 819 | 783 |